Are you in the market for an underwater welding helmet? Finding a reliable and quality-made welding mask is essential to protect yourself while working in hazardous conditions. In this guide, we’ll be exploring everything you need to know about selecting the best underwater welding helmet so that you can make an informed decision. So get ready to dive into our comprehensive review of all the features, specs and safety standards needed when it comes to finding that perfect welder’s mask!

Page Contents

What are the benefits of using an underwater welding helmet?

Using an underwater welding helmet provides several benefits, including protection from sparks, debris, and harmful radiation. It also improves visibility in dark or murky water conditions and ensures the welder’s safety by preventing water from entering the helmet.

Are you in the market for an underwater welding helmet? Finding a reliable and quality-made welding mask is essential to protect yourself while working in hazardous conditions. In this guide, we’ll be exploring everything you need to know about selecting the best underwater welding helmet so that you can make an informed decision. So get ready to dive into our comprehensive review of all the features, specs and safety standards needed when it comes to finding that perfect welder’s mask!

Advantages of an Underwater Welder Helmet

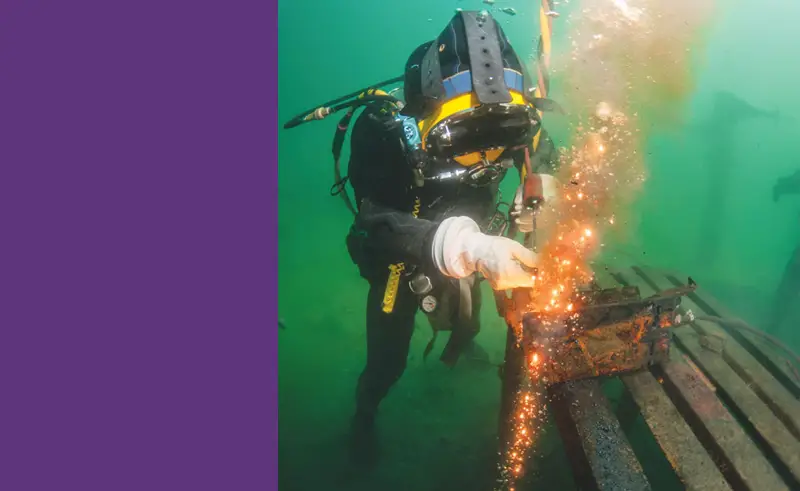

Underwater welding is a specialized form of welding that requires the use of a unique helmet to protect against the extreme conditions encountered in underwater work. An underwater welder’s helmet provides much needed protection from dangerous heat and pressure, as well as providing clear visibility for precise underwater welds.

The major advantage of an underwater welder’s helmet is its ability to provide superior protection from all types of hazards associated with deep-sea welding. Constructed from high quality materials, these helmets are designed to withstand intense pressures and temperatures while still allowing for maximum visibility and maneuverability during operations. The helmet also houses an oxygen supply system which helps ensure that the welder has sufficient air supply throughout their dive. Additionally, many models come equipped with features such as integrated communication systems, adjustable visors, or headlamps for improved illumination in darkness.

In addition to safety benefits, underwater welder helmets also help improve efficiency by reducing fatigue levels caused by long exposure times under water. By keeping the diver comfortable and relaxed they can focus more on completing their task rather than struggling through exhaustion or discomfort due to unsuitable equipment or environmental conditions. Furthermore, modern designs offer improved ergonomics which allow divers greater freedom of movement when performing complex tasks like repairing pipes or moving heavy objects around in cramped areas where traditional diving gear would be too cumbersome or restrictive to use effectively. Finally, some models even feature built-in cameras so that supervisors can monitor progress without having to enter hazardous environments themselves – saving time and money overall..

Types of Underwater Welder Helmets

When it comes to welding underwater, safety is of the utmost importance. The most important piece of equipment for a welder working underwater is their helmet. There are several different types of helmets available on the market today that provide welders with the protection they need in order to work successfully and safely underwater.

One type of helmet used by many professional divers and welders is an auto-darkening welding helmet. This type of helmet features a dark visor that automatically darkens when exposed to ultraviolet light from sparks created during welding, protecting the eyes from any potential damage caused by these intense bursts of light. It also provides superior visibility when compared to standard lensed helmets as it adjusts its tint accordingly depending on how bright or dim your environment is at any given time.

Another popular choice amongst divers and welders alike are flip up welding helmets. These particular models feature two separate lenses which can be flipped down over one another in order to protect your face while you’re doing underwater welding tasks such as grinding or cutting. They offer great convenience due to their lightweight design, making them easy and comfortable for long periods wear without causing fatigue or strain on your neck muscles like traditional heavy-duty helmets do.

Finally, full face masks are another option for those who require complete facial protection while working underneath watery depths – especially if there’s debris present in the area you’re working in! Full face masks provide 360 degree coverage around your head ensuring every inch gets adequate protection from flying particles that could otherwise cause injury if not properly safeguarded against them . Additionally, these masks usually come equipped with adjustable straps allowing you make sure fit snugly against your skin providing maximum levels comfort even after prolonged useage periods too!

Components and Features To Look For in an Underwater Welding Helmet

When it comes to underwater welding, having the right helmet is essential. Not only does an underwater welding helmet protect you from the intense heat and sparks of your work, but it also provides you with a clear view of what’s going on around you. With so many different helmets available, it can be difficult to know which components and features to look for when selecting one for yourself or your team.

The first thing that should be considered is whether or not the helmet meets all safety requirements. Look for a model that conforms to industry standards like ANSI/ISEA Z87.1-2015 as this ensures that they meet all necessary protection levels against impact, chemical splash and UV radiation exposure while working in hazardous environments. Additionally, certain models may provide extra insulation against electrical hazards so make sure to double check these specific ratings if needed.

Next are some key components and features that will help enhance performance:

• A high-grade auto darkening filter (ADF) – This allows welders to adjust their lens shade quickly based on application needs while helping reduce eye fatigue over long periods of time by providing consistently clear views even in conditions where glare is present

• Comfortability – Optimal fitment can make a huge difference in terms of comfort level during extended use sessions; look for adjustable straps and switchable headbands as well as lightweight materials used throughout construction

• Headgear compatibility – Many helmets have full modularity meaning multiple parts can easily be added or removed depending on your desired setup; accessories such as ear defenders can greatly improve user experience when dealing with extremely loud operating conditions

• Highly durable construction – Make sure any model selected has been tested under extreme temperatures and pressure situations since underwater welding requires specialized equipment able to withstand harsh environment changes without suffering permanent damage

Considerations When Purchasing An Underwater Welding Helmet

Underwater welding is a serious and dangerous job, so equipping yourself with the right safety gear is essential. The most important piece of equipment that you will need is an underwater welding helmet. When purchasing one, there are several things to consider:

First, think about what type of water environment you will be working in. Will it be fresh or salt water? Different helmets have different resistance levels when dealing with these different environments. Additionally, look at the overall durability of the helmet; if you are going to be doing frequent welds underwater then finding a helmet that can withstand long-term wear and tear should be at the top of your list when making your purchase decision.

Next evaluate how comfortable the helmet is for extended use over longer periods of time; heavy or uncomfortable helmets can create distractions while working which could lead to potentially hazardous situations underwater. Also consider whether or not a full face plate option would better suit your needs as opposed to just using goggles – this provides more protection against sparks and debris while also providing more visibility during work dives compared to traditional eyewear alone. Finally make sure that whatever model you choose has adjustable straps so that it fits snugly around head while allowing enough room for easy breathing and movement during work sessions under pressure depths below sea level!

Understanding And Maintaining Your Underwater Welding Helmet

An underwater welding helmet is a key component of any welder’s safety gear. Whether you are an experienced professional or just getting started in the craft, it is essential to understand how to maintain and care for your helmet correctly so that it provides maximum protection from potentially hazardous conditions. By following these simple steps, you can ensure that your helmet remains in top shape for many years to come.

First and foremost, it’s important to protect your helmet from damage by storing it properly when not in use. This means keeping it out of direct sunlight and away from other harsh environmental conditions like extreme temperatures or moisture. It should be kept wrapped up either in its original packaging or another protective cover such as a heavy-duty plastic bag. Additionally, check over the sealant on the faceplate every few months as this will deteriorate with time if not looked after properly – failure to do so could result in water seeping into the interior of the mask while working underwater!

Regularly inspect your welding helmet for any signs of wear and tear – cracks in the lens, worn seals around edges etc – as these need replacing immediately before use otherwise they may affect visibility during operations which could lead to serious injury or even death! Lastly, make sure you replace all filters at least once per year according to manufacturer’s instructions – this helps keep air clean inside the hood and reduce risk from breathing hazardous fumes produced during welds.

Safety and Comfort Tips for Using An Underwater Welding Helmet

Underwater welding helmets provide an extra layer of protection for welders working in aquatic environments. Not only do these helmets keep water and debris out of the eyes, they also protect against harmful UV rays emitted by the arc during welding. Here are some tips to ensure that your underwater welding helmet is used safely and comfortably:

First, be sure to wear protective clothing along with your helmet. This includes a long-sleeved shirt, trousers or overalls made from fire retardant material, gloves, safety goggles and hearing protection if necessary. Also make sure you have a full face mask so no water can get inside the helmet while diving down into the water. Additionally, it’s important to inspect all parts of the helmet before each use – check for any signs of corrosion or damage that could affect its performance. If there are any issues then replace them immediately as this will reduce potential risks when using it under demanding conditions.

It’s also helpful to adjust the tightness settings on your underwater welding helmet as needed throughout use – too tight can cause discomfort over time; too loose may allow water and other foreign particles inside which can lead to impaired vision or worse! A good rule of thumb is if you feel like it’s squeezing around your temples then loosen it slightly until you find a comfortable fit that doesn’t compromise safety standards either way – remember that even small adjustments can make big differences here! Finally double-check all connections between parts (like headbands) prior to entering any type of hazardous environment – just one weak link could spell disaster for both yourself and those around you so always stay vigilant!

Common Questions About Choosing The Right Underwater Welder Helmet

If you’re an underwater welder, then having the right equipment is critical to your safety and success. One of the most important pieces of gear for any diver is their helmet, as it must be able to provide protection from dangerous gases and keep out pressurized water during a dive. When choosing a welding helmet for underwater work, there are several factors to consider.

First and foremost, you’ll want something that fits comfortably on your head while still providing enough coverage so that no water can get in. A good rule of thumb when selecting an underwater welding helmet is getting one with a full face mask – this will give you the best visibility while also offering sufficient protection against potential hazards. It’s also important to make sure the material used in construction is strong and durable; look for helmets made with materials like polycarbonate or Kevlar which won’t easily break under pressure or wear down over time.

In addition, comfort should be taken into consideration when selecting an underwater welding helmet – if it doesn’t fit properly on your head, then it’s not going to do much good! Look for helmets designed specifically for divers with adjustable straps and padding around areas where chafing could occur; this way you can ensure maximum comfort even after extended periods of use. Finally, take into account the type of diving environment in which you plan on using your new helmet: some models may come equipped with features such as fog-resistant lenses or anti-reflective coating which will help improve visibility in murky waters or hazardous conditions.

Wrapping it Up!

In conclusion, the advantages of an underwater welder helmet are numerous. Different types of helmets have different components and features that must be considered when purchasing one. It is important to understand how to use and maintain your helmet for optimal safety and comfort. Finally, there are several common questions about which type of helmet is best for you depending on your needs. With so many different options available, finding the right underwater welder helmet can help ensure a safe and successful welding experience!

underwater welder salary michigan

Frequently Asked Questions!

Q: What factors should I consider when choosing an underwater welder helmet?

A: When selecting a helmet for underwater welding, look at the quality of the lenses and their ability to withstand pressure. Also, make sure that the helmet is comfortable enough to wear for extended periods of time and has adjustable straps or other features that enhance fit. Additionally, you’ll want to ensure that your chosen model offers adequate protection from light as well as heat generated by welding arcs.

Q: Are there any special requirements for helmets used in deep water welders?

A: Yes. In addition to meeting general safety standards and having strong lenses capable of withstanding high pressures, deep-water welding helmets must also be equipped with communication systems and external lighting sources so welders can see clearly while working in dark waters. Additionally, they must have extra layers of insulation against extreme cold temperatures found at greater depths.

Q: Is it possible to use my existing welding helmet for underwater work?

A: It depends on the specific design of your current helmet; some models are suitable for both dry land and submerged applications but may require additional modifications such as adding a breathing tube or attaching an air supply system before being used underwater safely. Therefore, it’s best to check with manufacturers or consult experienced professionals before attempting this type of project yourself.

Q: What types of materials are typically used in constructing an underwater welder’s helmet?

A: Typical construction materials include polycarbonate plastic shells reinforced by fiberglass mesh, rubber gaskets around lens edges for leak resistance, and neoprene straps which provide comfort while allowing divers full range of movement during tasks requiring precision manipulation tools like pliers or wire cutters etcetera. Moreover most modern designs feature integrated communications systems between worker(s) below surface & those above using either radio waves or Bluetooth technology depending on availability/cost factors involved etcetera…

Q : Do I need any special training prior to using an underwater welder’s helmet?

A : Yes – if you intend on performing work activities involving cutting metal under water then specialized instructions will be required prior commencing operations – these teachings may include topics such as buoyancy control techniques , familiarization with equipment operation procedures , troubleshooting common issues encountered whilst immersed etcetera . Moreover certified courses / classes offered by professional bodies would generally prove beneficial towards ensuring maximum safety whilst performing such hazardous tasks .